Nitrile Glove Production Line

nitrile gloves machine

Nitrile Glove Production Line Description

DEYI supplies powder-free nitrile gloves machine and latex-free gloves machine, the application fields of nitrile gloves are mainly electronic industry, packaging industry, or hospital outpatient service.

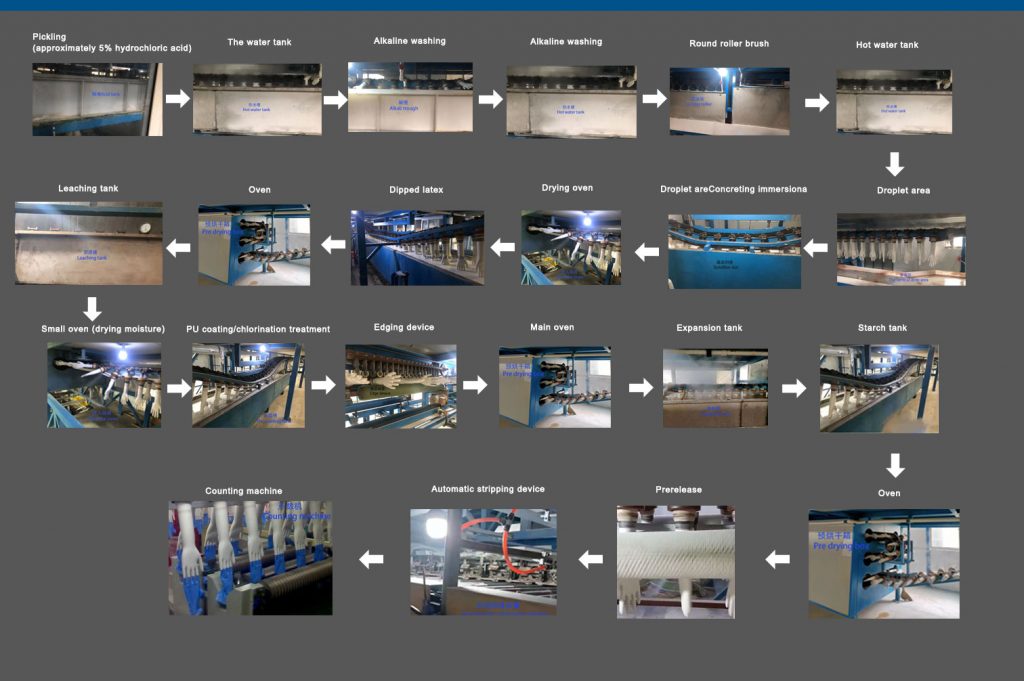

The nitrile & latex glove production line uses natural latex or synthetic rubber as the main raw material and other chemicals as auxiliary materials. The hand mold is cleaned with acid and alkali and then cleaned with water again. Then the cleaned hand mold is first immersed in hot water and heated then immersed into coagulant and dried for dipping. After dipping, go into an oven for preliminary drying, flushed with hot water, and then sent to another oven for curing and drying to form. After the gloves are demolded, they are inflated or filled with water for inspection, washed, centrifuged, and dried before packaging and sending them to the finished product warehouse.

The nitrile & latex glove production line uses natural latex or synthetic rubber as the main raw material and other chemicals as auxiliary materials. The hand mold is cleaned with acid and alkali and then cleaned with water again. Then the cleaned hand mold is first immersed in hot water and heated then immersed into coagulant and dried for dipping. After dipping, go into an oven for preliminary drying, flushed with hot water, and then sent to another oven for curing and drying to form. After the gloves are demolded, they are inflated or filled with water for inspection, washed, centrifuged, and dried before packaging and sending them to the finished product warehouse.

The following is the capacity of nitile gloves machine

The length of line(M) | Type-Hand mold | Capacity(Pcs/day) |

45 | single | 72000 |

50 | single | 86400 |

80 | single | 204000 |

100 | single | 240000 |

110 | single | 300000 |

110 | double | 720000 |

120 | double | 504000 |

140 | single | 380000 |

180 | double | 900000 |

Nitrile Glove Production Line Technical Parameter

1.Adopt the most advanced gloves production technology and production process layout, product qualification rate is more than 99%.

2.Imported surfactant solidifier, the finished membrane is uniform, no powder mold release.

3.The introduction of foreign advanced transmission main chain structure, chain little resistance during operation, Production of high speed, stable operation.

4. The main motor drag, solve the drag, difficult to synchronize, fault point, difficult maintenance, and other issues. 5.Mold directional, machine printing technology.

6. A variety of specifications of production, on the same edge automatic adjustment.

7.Can design according to the needs of customers of different lengths, heights, cost models.

Recommendation

The length of the workshop is suggested to be at least 10 meters longer than the production line, the width of a production line is suggested to be at least 15-20 meters, and the height is 1.5 meters higher than the production line.

The quotation of equipment provides the whole site plan. The customer only needs to supply water, electricity and energy (natural gas, coal, diesel, etc.) to the plant.

Aout wastewater: production line produced by wastewater accounts for about two-thirds of the total water consumption. There are several kinds of wastewater treatment:can look for local environmental protection company to provide water treatment equipment, some manufacturer to dig several reservoirs, respectively: the neutralization (add the corresponding chemical materials and chemical residues in wastewater), deepen (adding chemical additives, depth of processing wastewater), precipitation (the wastewater of chemical residues natural precipitation), drainage (tank water and chemical wastewater after stratification, the upper water direct emissions)

The attention of production line

Maintenance work of nitrile gloves machine mainly includes hand mold replacement, lubricating oil of chain slide, brush replacement, valve maintenance and electrical maintenance, etc.

The normal operation of nitrile gloves machine requires about 6-8 people in one shift, that is, 1 monitor, 1 inspect, 1 watchman, and 2 to 4 packers. Sulfur chemical does not need shift work, sulfur chemical requires 2-3 people

About Nitrile glove production line

- Nitrile glove production line is non-standard customized equipment, which can be customized according to the length, width, and height of the customer’s workshop. The production line is divided into the single mold and double mold. The advantage of a single hand is more convenient to replace the hand mold, and the advantage of a dual mold is high output.

latex/nitrile gloves production line can produce latex and nitrile gloves. When producing powder free gloves, nitrile gloves are chlorinated, while latex gloves can only be coated with PU coating. However, the effect of both powder free gloves is the same, which can prevent adhesion and make wearing smooth.

If there are powder gloves, add talc powder or calcium carbonate and modified starch into the starch tank. If there are no powder gloves, add hot water.

It is recommended to clean the glue tank of the production line once every half a month. There will be condensate in the glue tank for a long time